Dust Removal Air Filter Cartridge 280x195

Product SpecificationsHuahang

Dimension |

280x195 |

Filter layer |

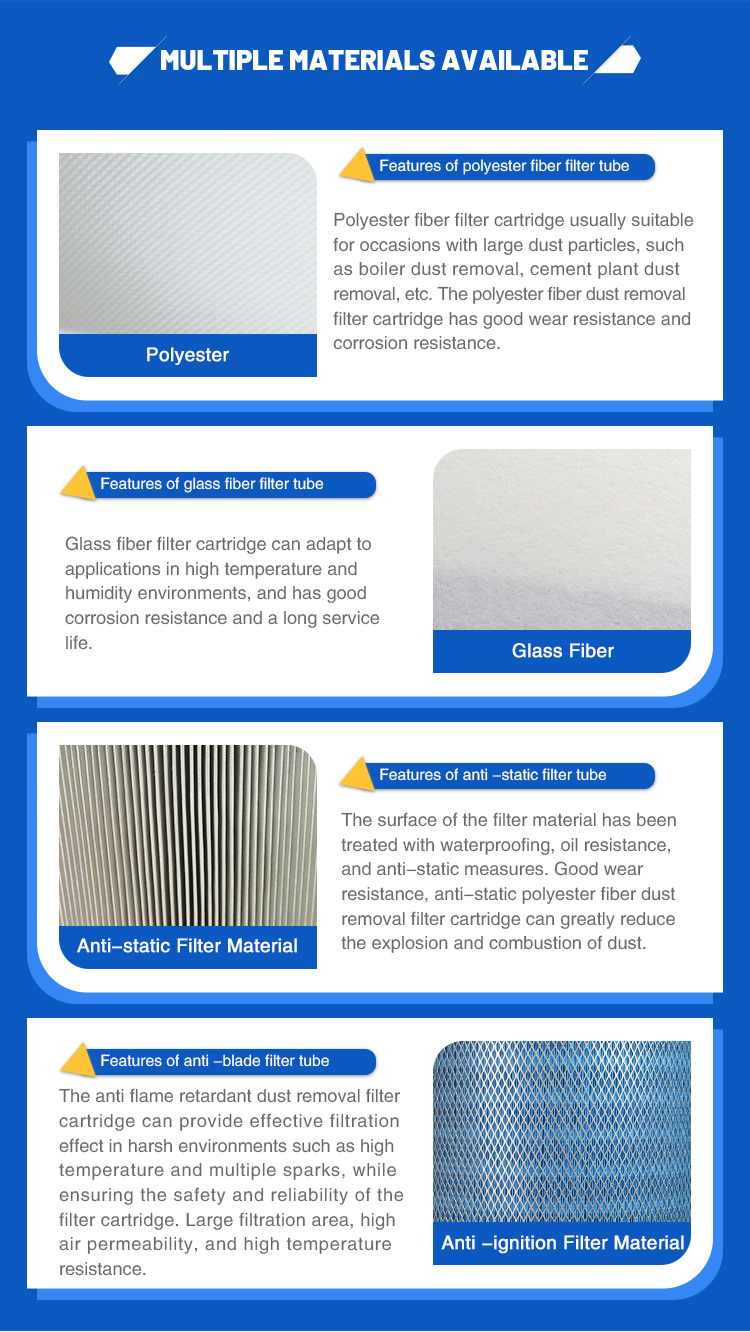

Fabric/Fiberglass |

End caps |

Carbon steel |

Skeleton |

Zinc infiltrated diamond mesh |

Sealing ring |

Black adhesive strip |

Product FeaturesHuahang

(1) The filter element is not only wear-resistant, acid and alkali resistant, but also has high strength;

⑵ It has good breathability, a large filtration area, and low resistance during operation. Compared with traditional filter bags, the filtration area can be increased several times and the efficiency can be improved;

⑶ It can be reused after cleaning, with a long service life;

(4) The product has good anti-static function and is widely used;

(5) The filter element can be installed in the filtering area of pulse backflow and direct dust removal (suitable for vertical and horizontal installation);

(6) It can be applied in powder dust removal (recovery) in the petroleum and petrochemical industries, as well as dust removal and dust capture recovery in pharmaceutical, glass production lines, cement production lines, and sandblasting operations.

1. Quick disassembly installation of chuck:

This installation method involves fixing the filter cartridge mounting cap on the mounting plate, and then inserting the filter cartridge's claw into the slot of the mounting cap. By rotating, the sealing ring is fully in contact with the top of the mounting cap to achieve sealing.

2. Screw installation:

In this installation method, the mounting hole of the filter cartridge needs to be aligned with the screw and then tightened by rotating the nut to ensure that the filter cartridge is fixed in place. This installation method is suitable for vertical, side, and oblique placement installation of filter cartridges.

In addition, there are several other installation methods for dust removal filter cartridges, including:

3. Screw installation: suitable for vertical, side, and oblique placement installation of filter cartridges. The filter cartridge is inserted through a threaded rod and a tripod, and the top sealing ring contacts the dust collector mounting plate. Then, the nut is rotated and tightened to fix the filter cartridge, and the sealing ring fully contacts the mounting plate.

Flange installation: Unlike screw installation, flange installation requires opening the top end cover of the dust collector and installing the filter cartridge from top to bottom. The advantage of this method is that it is easy to install, but it requires the screw position to correspond to the flange hole position.

4. Quick release installation: The upper end cover of the filter cartridge adopts a six claw plastic end cover, and the installation cap contains a slot for the six claws to be inserted. By rotating, the sealing ring is fully in contact with the top of the installation cap. This installation method is simple and convenient for replacing the filter cartridge.

Application areaHuahang

1. In the machine tool industry, 85% of machine tool transmission systems use hydraulic transmission and control. Such as grinding machines, milling machines, planers, drawing machines, presses, shearing machines, and combination machine tools.

2. In the metallurgical industry, hydraulic technology is used in electric furnace control systems, steel rolling mill control systems, open furnace loading, converter control, blast furnace control, strip deviation, and constant tension devices.

3. In construction machinery, hydraulic transmission is commonly used, such as excavators, tire loaders, truck cranes, crawler bulldozers, tire cranes, self-propelled scrapers, graders, and vibrating rollers.

4. Hydraulic technology is also widely used in agricultural machinery, such as combine harvesters, tractors, and plows.

5. In the automotive industry, hydraulic off-road vehicles, hydraulic dump trucks, hydraulic aerial work vehicles, and fire trucks all use hydraulic technology.

6. In the light textile industry, hydraulic technology is used in plastic injection molding machines, rubber vulcanization machines, paper machines, printing machines, and textile machines.

Shay

Shay