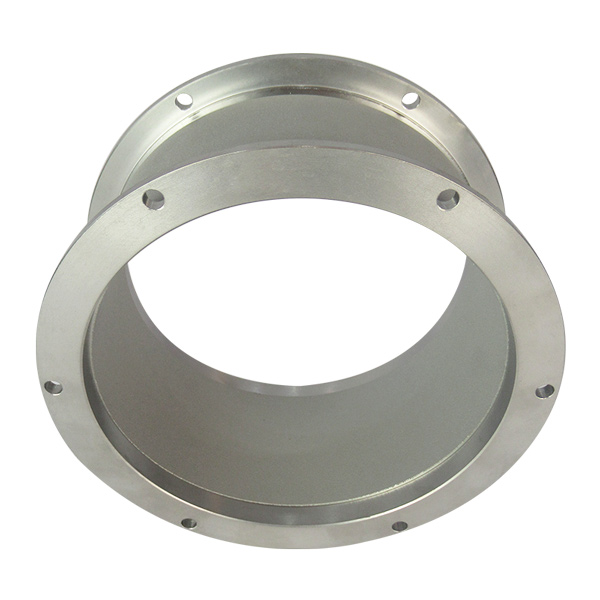

Sintered Powder Filter Element 170x80

Product SpecificationsHuahang

Dimension |

170x80 |

Filter layer |

304/316L |

Type |

Sintered powder filter element |

Filtration accuracy |

1~25μm |

Interface |

Flange |

FeaturesHuahang

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

1. Large pollution capacity, high filtration accuracy, slow pressure rise, and long replacement cycle.

2. High porosity and excellent permeability, low pressure loss, and high flow rate.

3. It is resistant to high pressure, high temperature, and corrosion, and can be used for a long time in an environment of 480 ℃.

4. Easy to process, shape, and weld.

5. We can produce reinforced, thickened, single or double protective nets and various other specifications according to user requirements.

1. Efficient filtration: Fiberglass filters have very small pore sizes, which can filter out small particles and impurities in water, greatly improving water quality.

2. Chemical corrosion resistance: Fiberglass filters have characteristics such as acid resistance, alkali resistance, and high temperature resistance, and can also be used normally in chemical environments.

3. Long service life: Fiberglass filters usually have a longer service life than ordinary filters, usually reaching more than six months.

4. Easy to maintain: The maintenance of fiberglass filter is relatively simple, only requiring regular cleaning or replacement, and the maintenance cost is relatively low.

NOTEHuahang

1. Powder quality control: Strictly control the quality of stainless steel powder to avoid the presence of impurities and non-metallic inclusions, in order to prevent negative effects on product performance

2. Processing technology control: Control the sintering temperature, pressure, time and other process parameters to ensure the smooth formation and sintering process of stainless steel powder, and achieve the required material density and mechanical properties

3. Sealing and anti oxidation treatment: Stainless steel powder is easily affected by oxidation during the processing, so appropriate measures need to be taken for sealing and anti oxidation treatment to ensure the quality and performance of the powder

4. Reasonable mold design: Based on the shape and size requirements of the product, design a reasonable mold and ensure uniform filling and exhaust inside the mold to obtain high-quality molded parts

5. Appropriate post-treatment: According to the needs, appropriate post-treatment should be carried out on the formed parts, such as heat treatment, surface treatment, etc., to improve their performance and corrosion resistance

Corrosion resistance:

304 stainless steel: has good resistance to oxidizing acids, alkalis, salts, etc., and is suitable for general environments.

316 stainless steel: With the addition of 2-3% molybdenum element, it has stronger corrosion resistance, especially in chloride environments (such as seawater, saltwater, etc.), and is suitable for harsh environments.

Strength and hardness:

304 stainless steel: With high strength and hardness, it is more suitable for high temperature and high pressure environments, such as pipeline systems, tableware, and kitchenware.

316 stainless steel: slightly inferior to 304 stainless steel in this regard, but has better stability in high temperature environments than 304, making it more suitable for working in high temperature and high pressure environments.

Application field:

304 stainless steel: widely used in construction, kitchenware, medical equipment, automotive components and other fields, meeting general usage requirements and having lower costs.

316 stainless steel: more suitable for fields with high material requirements such as marine engineering, chemical equipment, pharmaceutical equipment, etc.

Cost:

304 stainless steel has a relatively low price, fewer alloy components, and a simple production process, making it the preferred material in many industries.

316 stainless steel has a higher price due to its special alloy composition and higher corrosion resistance.

1. Home: Fiberglass filter is suitable for water purifiers, water dispensers, and other equipment in homes. It can filter out small particles, residual chlorine, odors, and other pollutants in water, improving the quality of drinking water.

2. Industry: Fiberglass filters are widely used in industrial fields such as water treatment, wastewater treatment, and high-purity water preparation, and can remove various pollutants from water.

3. Medical: Fiberglass filters are also suitable for use in the medical field, such as operating room purification and laboratory water purification in hospitals.

Shay

Shay