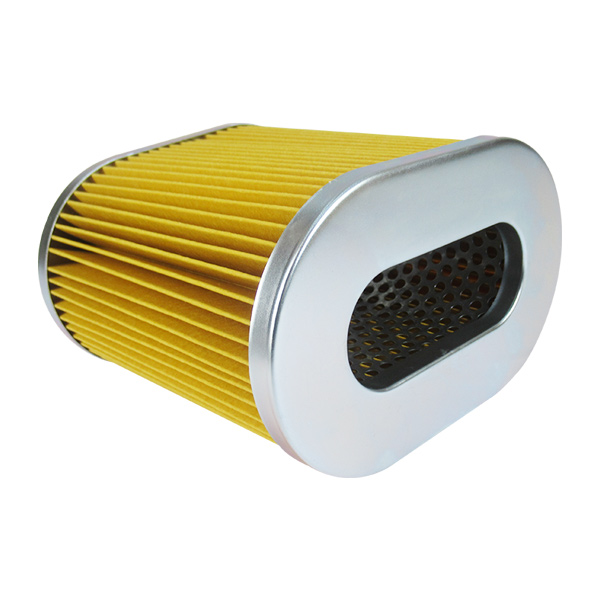

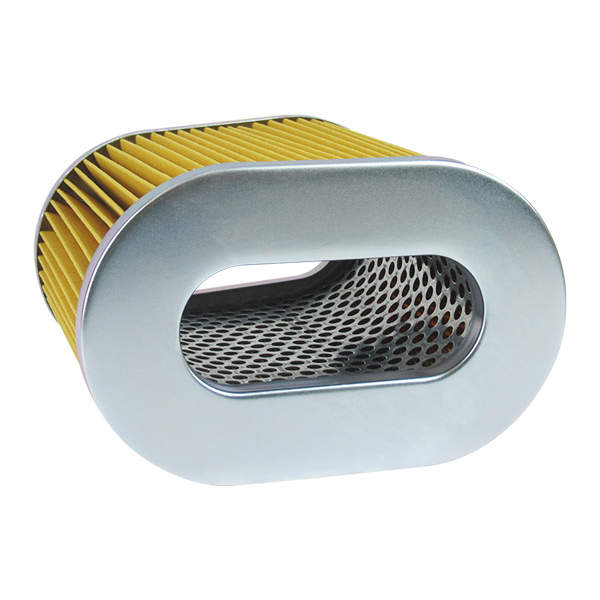

Custom Paper Oil Filter Element

Product SpecificationsHuahang

End caps |

Carbon steel |

Filter layer |

Paper |

Inner skeleton |

Carbon steel punched plate |

Filtration efficiency |

≥99.9% |

faqHuahang

Q: How long can a customized paper oil filter be used?

Answer: The service life of customized paper oil filters may vary due to many factors, such as the quality of the oil used and driving conditions. However, they aim to provide excellent durability, typically lasting up to 12000 miles.

Q: Is custom paper oil filter easy to install?

Answer: Yes, the customized paper oil filter design is easy to install and can be installed using standard tools in just a few minutes. In addition, they also come with detailed instructions that can guide you through the entire process.

Q: How to ensure that the custom-made paper oil filter element matches my vehicle correctly?

Answer: Customized paper oil filter elements are designed to adapt to various vehicle brands and models. However, please make sure to check the manufacturer's specifications to ensure they are suitable for your specific vehicle.

1. Filtering accuracy

The filtration accuracy of filter paper is influenced by factors such as fiber characteristics, fiber distribution, and fiber arrangement. Generally speaking, the filtration accuracy of filter paper ranges from 0.5 μ m to 50 μ m. The filtration accuracy of the filter is generally determined by the size of the mesh, and can usually reach below 0.5 μ m.

2. Scope of application

Filter paper is suitable for filtering small particles and liquids in analytical experiments, food industry, pharmaceuticals, and other fields. The filter is suitable for filtering large particles and rough materials, with good corrosion resistance and mechanical strength.

3. Price and maintenance costs

The price of filter paper is relatively low, but its service life is short and requires frequent replacement. The price of the filter is relatively high, but it has a longer service life and can be cleaned and maintained multiple times.

1、 Material standards

The main materials for oil filter cartridges are cellulose, polypropylene, polyamide, stainless steel, etc. These materials should comply with relevant national standards, for example, cellulose should meet the requirements specified in GB/T20582-2006.

2、 Production process standards

The production process of oil filter cartridges includes textile, pressing, and assembly processes. Among them, the textile production process should comply with the relevant provisions in GB/T 5270-2005; The pressing production process should comply with the relevant provisions in GB/T 17656-2018; The assembly production process should comply with the relevant provisions in GB/T 25153-2010.

3、 Performance testing standards

The performance testing of oil filter elements includes resistance testing, dust capacity testing, service life testing, etc. Among them, the resistance test should comply with the relevant provisions in GB/T13310-2008; The dust capacity test should comply with the relevant provisions in GB/T14295-2012; The service life test should comply with the relevant provisions in GB/T25152-2010.

4、 Quality inspection standards

The quality inspection standards for oil filter cartridges include general appearance inspection, dimensional inspection, filtration efficiency inspection, etc. Among them, the general appearance inspection should comply with the relevant provisions in GB/T25154-2010; Dimensional inspection should comply with the relevant provisions in GB/T14727-2013; The filtration efficiency test should comply with the relevant provisions in GB/T25152-2010.

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

NOTEHuahang

When starting the oil filter, be careful not to reverse the oil pump to avoid causing the oil pump shaft seal to break and air intake. When confirming the rotation of the oil pump, the inlet and outlet ball valves should be opened in a timely manner for filtration operation.

When using an oil filter device, the oil pump may introduce air, which may affect the flow rate of the oil pump. In order to achieve the rated flow rate of the oil filtration device and ensure the normal operation of the fine filter element, the exhaust valve should be opened in a timely manner and the filter should be removed. After emptying the air (i.e. oil is discharged from the exhaust valve), the exhaust valve can be closed.

3. After using the oil filter for a period of time, the surface of the filter element will be blocked by pollutants, resulting in poor oil suction effect and excessive oil pump noise, indicating that the filter element has been severely blocked. Before continuing to use, the oil filter element should be replaced;

After using the secondary filter for a period of time, pollutants gradually block the secondary filter, causing an increase in filter pressure. When the pressure reaches 0.4 Ma, it is necessary to replace the filter element in a timely manner.

Shay

Shay