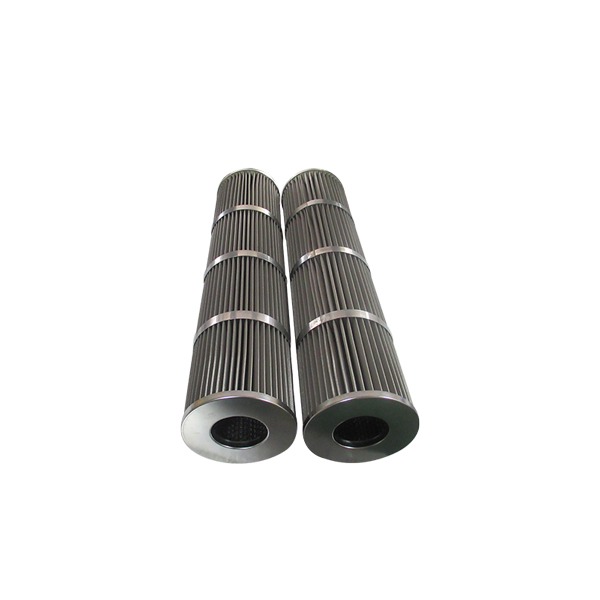

304 Stainless Steel Water Filter Element

Product SpecificationsHuahang

Filtration accuracy |

5~25μm

|

Filter layer |

304 Stainless steel |

Dimension |

159x680 |

End caps |

304 stainless steel |

features

HUAhANG

Strong corrosion resistance: Stainless steel has good corrosion resistance, can work stably in various harsh environments, and can maintain its filtration performance for a long time.

Good high-temperature resistance: Stainless steel material has good high-temperature performance and can be used normally in high-temperature environments without softening or embrittlement.

High strength: Stainless steel material has high strength, can withstand large pressure and extrusion force, and is not easy to deform or break.

Lightweight: Compared to other materials of filters, stainless steel filters have a lighter weight and are easy to handle and replace.

Good cleaning performance: The stainless steel filter element has good cleaning performance, which can be repeatedly cleaned and reused, reducing the cost of use and maintenance.

Long lifespan: Due to the strong corrosion resistance, high temperature resistance, and high strength advantages of stainless steel material, its lifespan is relatively long, which can greatly reduce the frequency and cost of replacing filter elements.

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Working principleHuahang

1. Diffusion deposition: Due to Brownian motion, the trajectory of each fine particle is not consistent with the direction of compressed air flow. With particles

As the size decreases, the intensity of Brownian motion increases, the probability of collision between fine particles and fibers also increases, and the diffusion deposition effect becomes stronger.

2. Direct interception: This mechanism is related to the size of particles. When the gap between fibers is smaller than the diameter of particles, the particle

The particles were intercepted.

3. Inertial deposition: When compressed air passes through fibers, the streamline will bend. Due to the effect of inertia, the

The particles do not follow the curved streamline and are thrown onto the fibers and deposited there. Obviously, this inertial effect will strengthen with the increase of particle size and the flow rate of compressed air.

4. Gravity deposition: Various particles have a certain settling speed due to the action of gravity. Therefore, the motion trajectory of particles is related to the use of

The streamline deviation of compressed air can cause particles to touch fibers.

5. Electrostatic deposition: Both particles and fibers may carry charges, so particles can deposit on fibers due to the interaction and induction forces between charges.

Q1: What are the benefits of using 304 stainless steel filter?

A: The use of 304 stainless steel filter has many benefits, including improving oil cleanliness, enhancing mechanical performance, extending service life, and reducing maintenance and repair costs.

Q2: What are the specifications of 304 stainless steel filter element?

A: The 304 stainless steel filter is made of high-quality stainless steel and is designed to be compatible with a range of automobiles and industrial machinery. It has a long service life and is easy to clean and reuse multiple times.

Q3: How to install a 304 stainless steel filter element?

A: The 304 stainless steel filter adopts a simple screw in installation process design, which can be completed in just a few minutes.

2. Acid cleaning method

Dissolve potassium dichromate or crystals in water to 60 to 80 degrees, and slowly add concentrated sulfuric acid with a concentration of 94% until sufficient. Add slowly and stir. Add up to 1200 milliliters of potassium sulfate or completely dissolve, and the solution will appear dark red in color. At this time, the rate of adding concentrated sulfuric acid can be accelerated until it is completely added. If there are still undissolved crystals after adding concentrated sulfuric acid, they can be heated until dissolved. The function of cleaning solution is to remove general pollutants, grease, and metal particle impurities on the wall of stainless steel filter cartridge, and it can effectively kill the bacteria and microorganisms that grow on the filter cartridge and damage the heat source. If the filter element has been alkaline washed before, the alkaline solution must be washed first, otherwise fatty acids will precipitate and contaminate the filter element.

Shay

Shay