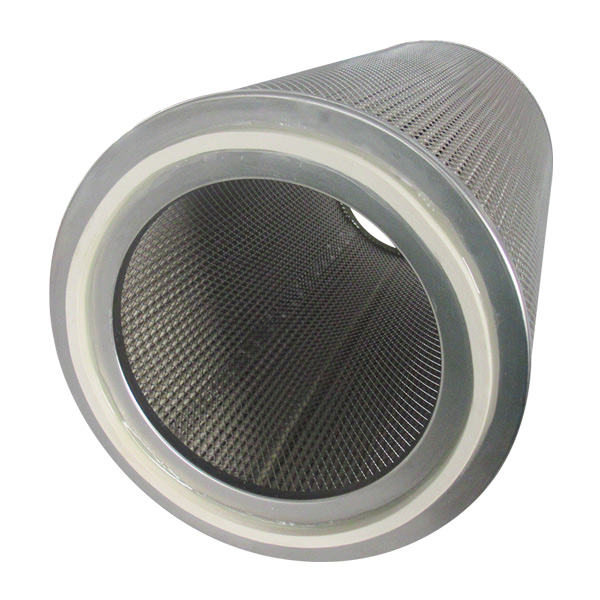

Dust Collect Filter Cartridge 350x660

Product SpecificationsHuahang

Dimension |

350x660 |

Filter layer |

High temperature resistant aramid |

Type |

Dust collection filter cartridge |

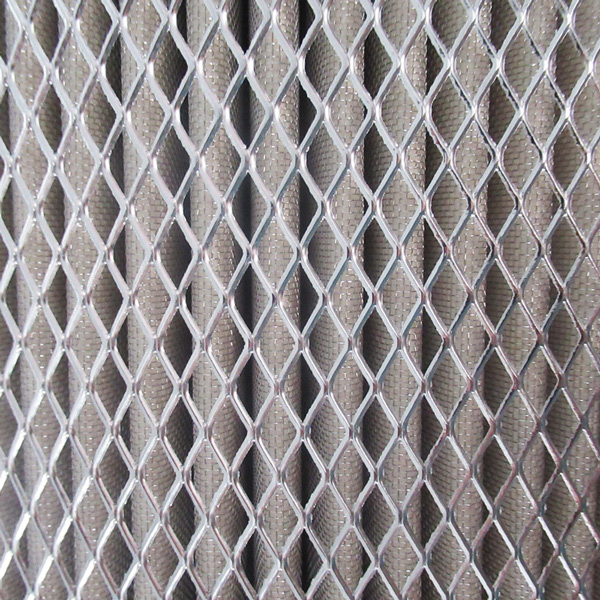

Skeleton |

304 diamond mesh |

End caps |

304 |

Product FeaturesHuahang

(1) The filter element is not only wear-resistant, acid and alkali resistant, but also has high strength;

⑵ It has good breathability, a large filtration area, and low resistance during operation. Compared with traditional filter bags, the filtration area can be increased several times and the efficiency can be improved;

⑶ It can be reused after cleaning, with a long service life;

(4) The product has good anti-static function and is widely used;

(5) The filter element can be installed in the filtering area of pulse backflow and direct dust removal (suitable for vertical and horizontal installation);

(6) It can be applied in powder dust removal (recovery) in the petroleum and petrochemical industries, as well as dust removal and dust capture recovery in pharmaceutical, glass production lines, cement production lines, and sandblasting operations.

Quick disassembly and installation of the chuck involves fixing the filter cartridge installation cap onto the installation plate, then inserting the filter cartridge's clamp into the slot of the installation cap, and rotating it to make the sealing ring fully contact the top of the installation cap, thereby achieving quick installation and disassembly of the filter cartridge. The advantage of this method is that when replacing the dust removal filter cartridge, it can be easily removed and replaced by reverse rotation, and the operation is simple and fast.

Screw installation involves aligning the installation hole of the filter cartridge with the screw, threading it through the screw, and then rotating and tightening it with a nut to ensure that the filter cartridge is firmly fixed on the installation plate. This method provides stable support and fixation through the tightening effect of screws and nuts, and is suitable for application scenarios that require high stability and sealing.

preparation workHuahang

Q1: How often should the filter element be replaced?

A1: The frequency of replacement depends on several factors, such as the amount of dust generated, the type of dust, and the airflow rate. Usually, it is recommended to replace the filter element when the pressure drop on the filter reaches a certain level, usually around 8-10 inch water meters.

Q2: How do I know if the filter element needs to be replaced?

A2: The pressure drop on the filter can be measured using a pressure gauge or pressure gauge. If the pressure drop exceeds the recommended level, it is time to replace the filter element. In addition, visual inspection of the filter medium can reveal signs of damage or blockage.

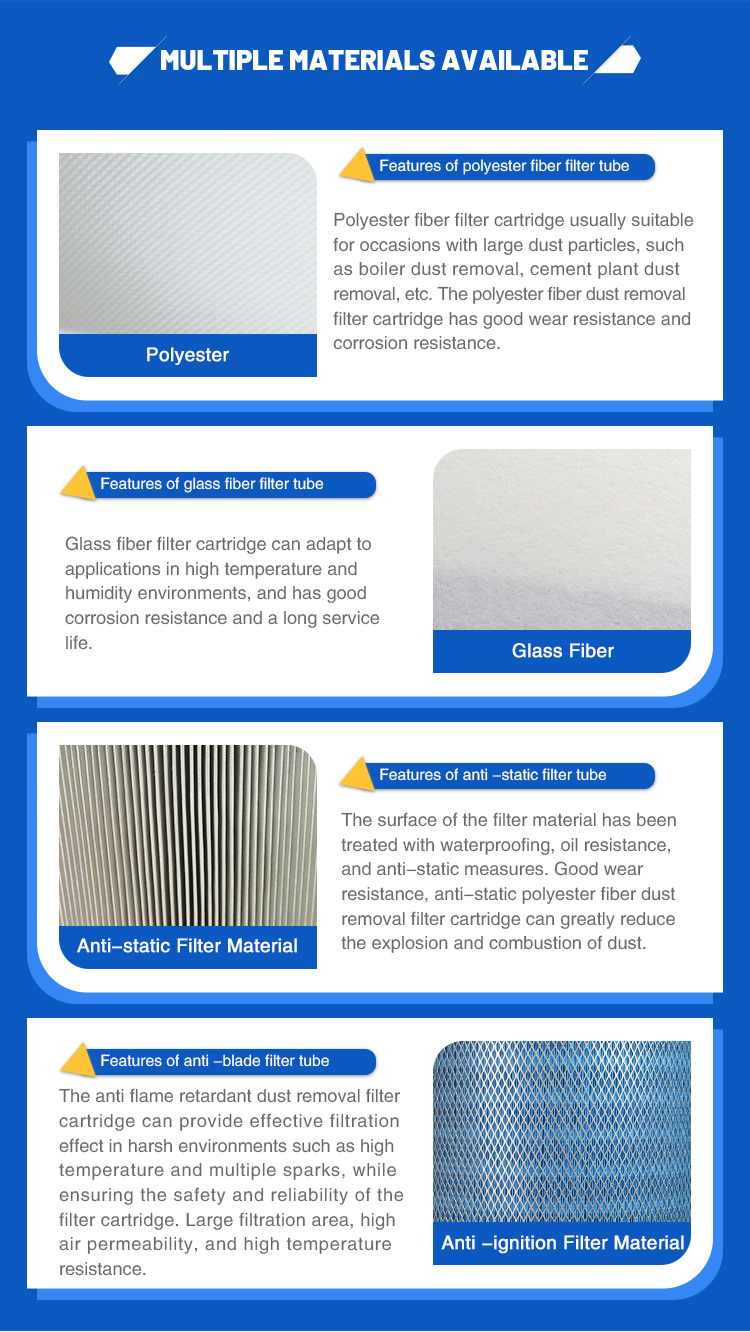

Q3: Are there different types of dust collection filters available?

A3: Yes, there are various types of dust removal filters designed to capture dust particles of different sizes and types. Some popular types of filter media include spunbond polyester, nanofiber media, and high-efficiency wrinkled media.

Shay

Shay